MECACONCEPT,

SPECIAL MACHINES &

TURNKEY EQUIPMENT

BECAUSE YOUR BUSINESS IS UNIQUE

SO ARE OUR SOLUTIONS !

Do you need specific equipment but can't find standardized solutions on the market?

Are you looking for a partner to design and build your custom equipment and machinery?

YOUR NEEDS

- Modernize your production facilities,

- Increase your production capacity,

- Automate your end of line,

- Replace worn-out equipment,

- Relieve your operators,

- Move from an R&D project to the industrialization phase,

- Automate quality control

MECACONCEPT

stands out for its ability to provide concrete solutions to a wide range of industrial problems.

- Special machines,

- Production or assembly lines

- End-of-line and packaging,

- Automated or semi-automated workstations,

- Test or trial benches,

- Quality control machines,

- Customized handling equipment,

- Stacker cranes,

- Case erectors

A PASSION FOR TECHNOLOGY AND A TASTE FOR INNOVATION

MECACONCEPT is above all a dynamic, seasoned team with a passion for technology. Thanks to its cross-disciplinary expertise in mechanics, robotics, automation, vision and industrial IT, MECACONCEPT is able to support you on complex projects.

MACHINES “MADE IN FRANCE”

DELIVERED AND INSTALLED ON ALL FIVE CONTINENTS

Since 1992, we have been committed to building high-performance, reliable and safe equipment. We use only top-quality industrial components, guaranteeing longevity and ease of maintenance over time. Particular attention is paid to safety and ergonomics.

All our equipment is built in compliance with the 2006/42/EC machine directive (and UL standards for the American market, for example) and certified as compliant by an authorized external body.

Made in France machines installed abroad: we design and build machines directly at our premises in Roche la Molière, near Saint Etienne. Our technical teams install and maintain our equipment both in France and abroad.

ISO 2001-certified since 1997, we work with SMEs, small and medium-sized businesses and large corporations in the aeronautical, agrifood, pharmaceutical, medical, nuclear, chemical and capital goods industries. Our teams are well versed in the requirements and constraints of each of these sectors.

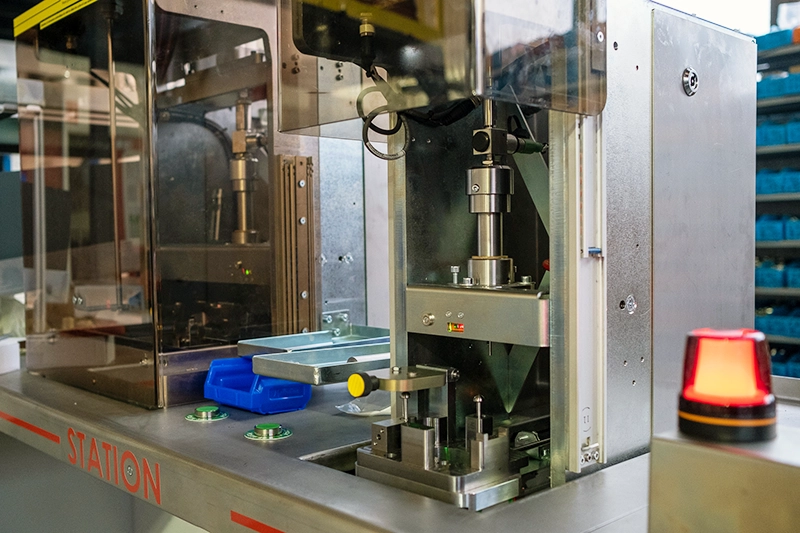

In-line quality control machine

Packaging unit

Customized workstations

OUR PROJECT APPROACH

UPSTREAM OF THE PROJECT

We pay particular attention to this essential stage, which enables us to qualify your project and propose efficient solutions.

- Analyze your specifications

- Collect additional information

- Listen and discuss with you and your teams

- Search for technical solutions

- Work on functionalities and uses

- Share our technical choices with you

- Answer technical and organizational questions

- Establish a budget to evaluate ROI

- Draw up a 3D preliminary project

- Draw up a detailed technical-commercial offer

- Draw up a schedule

- Be clear so that you can decide

INTERNAL DEVELOPMENT

By entrusting the development of your equipment to MECACONCEPT, you can count on the professionalism of a committed team who will be with you every step of the way.

- mechanical / calculation note

- automation

- electrical / pneumatic

- Assembly / Wiring

- Fine-tuning in our workshops

- On-site integration

- Ramp-up assistance

- Operators

- Maintenance

- Automatician

Maintenance

- Preventative maintenance

- Curative maintenance

- Remote maintenance

TESTIMONY

MECACONCEPT has always demonstrated great ability to meet our needs. Their solutions are pragmatic, simple, effective and maintainable.